For spray foam contractors, selecting the appropriate mix chamber size is crucial for achieving optimal results and efficiency. The optimal chamber size can significantly impact your productivity, material usage, and overall job quality. Let's explore the key factors to consider when choosing a mix chamber for your spray foam projects.

Understanding Mix Chamber Sizes

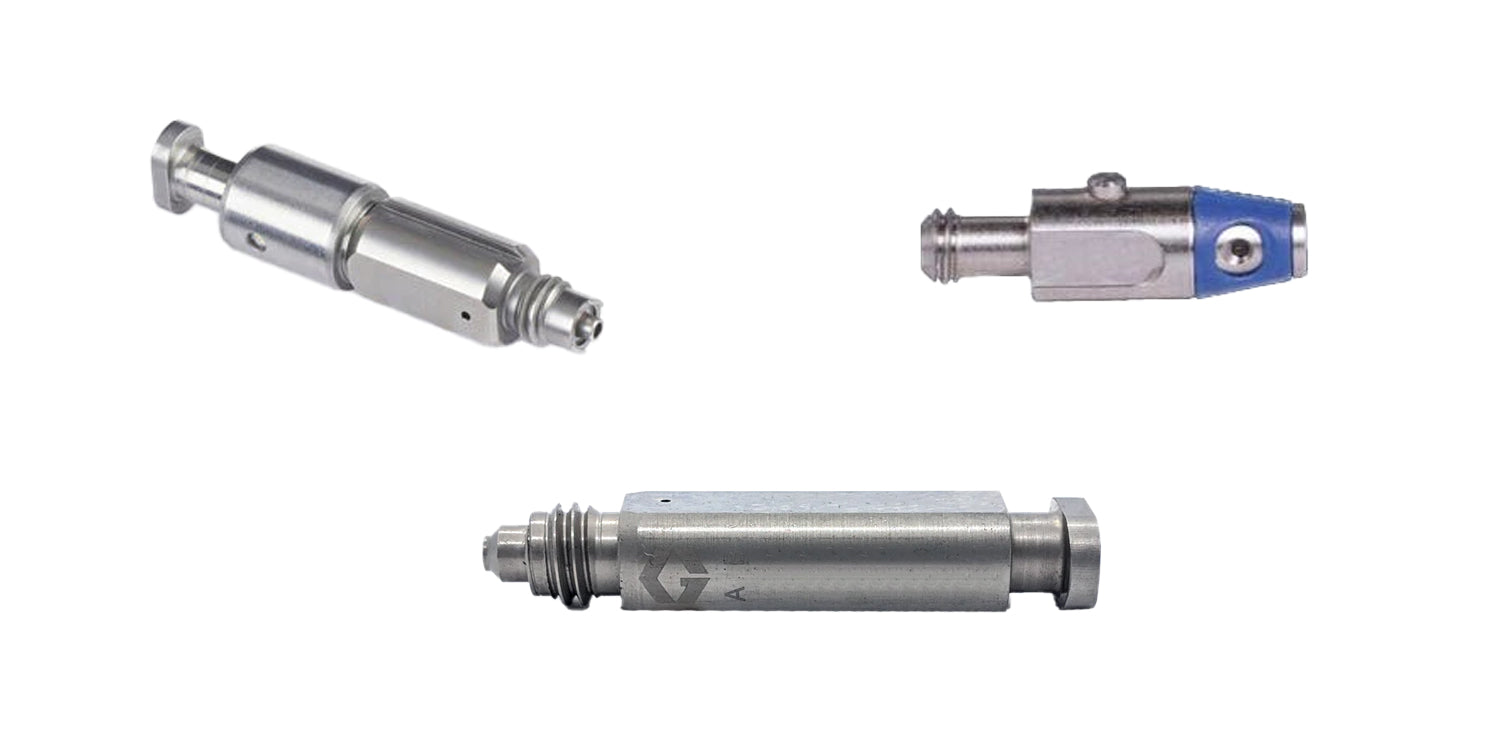

Mix chambers come in various sizes, typically denoted by numbers such as AR29, AR42, and AR60. These numbers correspond to the chamber's output capacity in pounds per minute and the spray pattern width:

- AR29: 7 lbs/min, 7-inch pattern

- AR42: 9 lbs/min, 11-inch pattern

- AR60: 19 lbs/min, 14-inch pattern

Factors to Consider

Project Scale

The size of your project plays a significant role in chamber selection:

- Small projects or detailed work: Smaller chambers like the AR29 offer more control

- Medium-sized residential jobs: AR42 is popular for its versatility

- Large commercial or industrial applications: Larger chambers like the AR52 or AR60 increase productivity

Application Precision

Consider the level of detail required:

- Smaller chambers (AR29) provide better control for precise applications

- Larger chambers are suitable for covering expansive areas quickly

Operator Comfort and Fatigue

Chamber size affects the physical demands on the operator:

- Smaller chambers reduce arm fatigue during prolonged use

- Larger chambers may require more strength and endurance to handle effectively

Material Viscosity

Different spray foam formulations may require specific chamber sizes:

- Low-viscosity foams can be applied effectively with smaller chambers

- High-viscosity materials often work better with larger chambers

Balancing Speed and Control

Finding the right balance between speed and control is essential:

- AR29 chambers provide excellent control for detailed work or less experienced operators

- AR42 chambers offer a good middle ground, suitable for most residential applications

- Larger chambers like the AR52 increase speed but may sacrifice some precision

Choosing the right mix chamber size is a critical decision for spray foam contractors. Consider your typical project types, desired application precision, and operator comfort when making your selection. Remember, it's often beneficial to have multiple chamber sizes available to adapt to different job requirements. By selecting the appropriate mix chamber, you can enhance your efficiency, reduce material waste, and deliver high-quality results for your clients.