Spray foam technology has evolved significantly over the years, with spray guns being a pivotal element in this development. Understanding the evolution of spray guns is crucial for professionals in the foam industry to appreciate the advancements made and to choose the right tools for their projects.

From Basic to Advanced: A Timeline

The journey of spray guns from basic, manually operated tools to highly sophisticated, automated systems reflects the industry's commitment to efficiency and precision. Early models were simple in design and function, but as the demand for better insulation grew, so did the complexity and capabilities of spray guns.

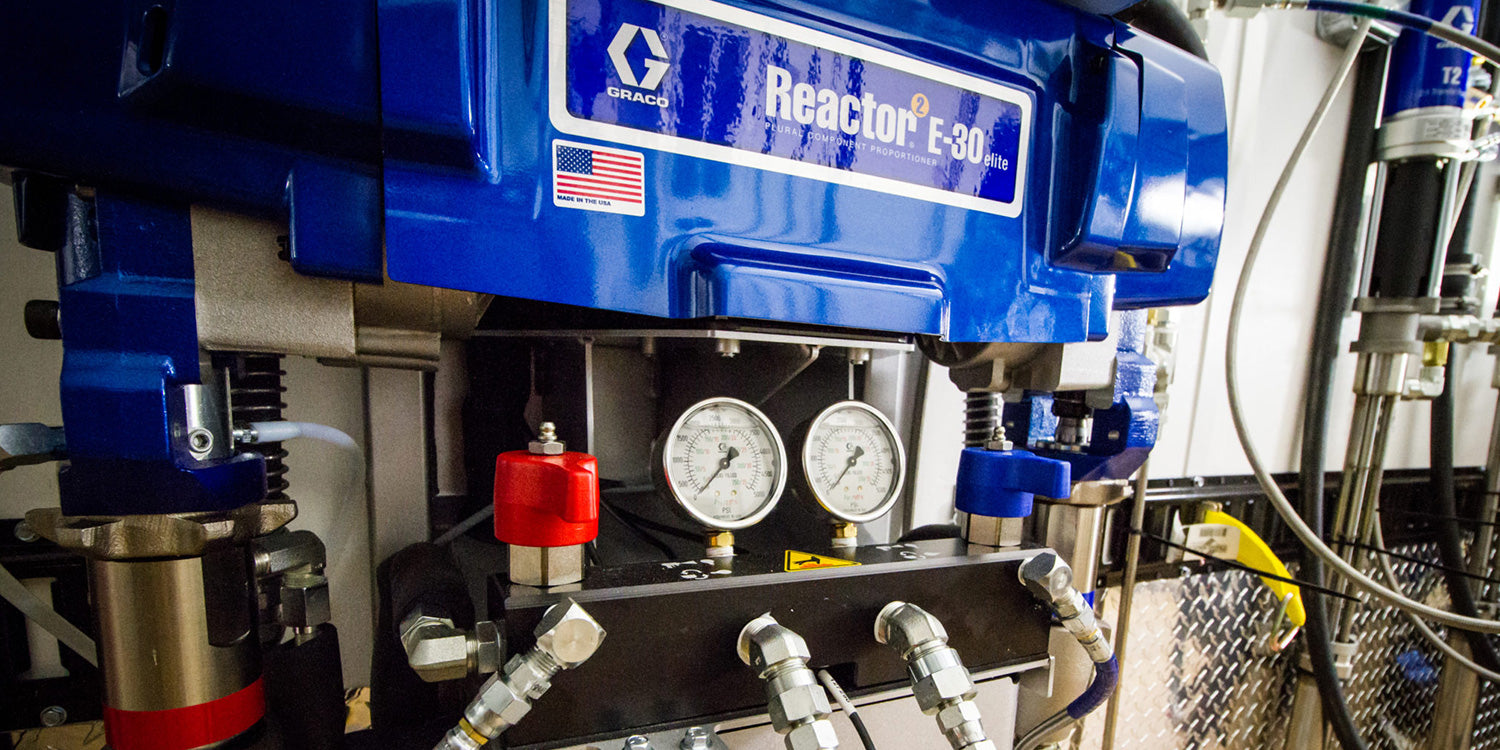

Technological Advancements

Modern spray guns are equipped with features like adjustable spray patterns, enhanced control mechanisms, and materials compatible with a variety of foam types. This progress has not only improved application efficiency but also expanded the range of possible uses.

Impact on the Industry

The evolution of spray guns has had a profound impact on the foam insulation industry. It has led to:

- Improved Application Quality: Enhanced precision and control in foam application.

- Increased Efficiency: Faster application times and reduced material waste.

- Broader Application Spectrum: Ability to tackle a wider range of projects, from residential insulation to industrial applications.

The Future of Spray Guns

Looking ahead, the industry anticipates further advancements in spray gun technology, including more environmentally friendly options and even greater precision. Staying abreast of these developments is essential for professionals looking to remain competitive and offer the best solutions to their clients.