Proportioners play a critical role in the spray foam and protective coatings industry. Regular maintenance of these machines is essential for optimal performance and longevity. This article will explore key maintenance tips to ensure your proportioners function efficiently.

Understanding Proportioners

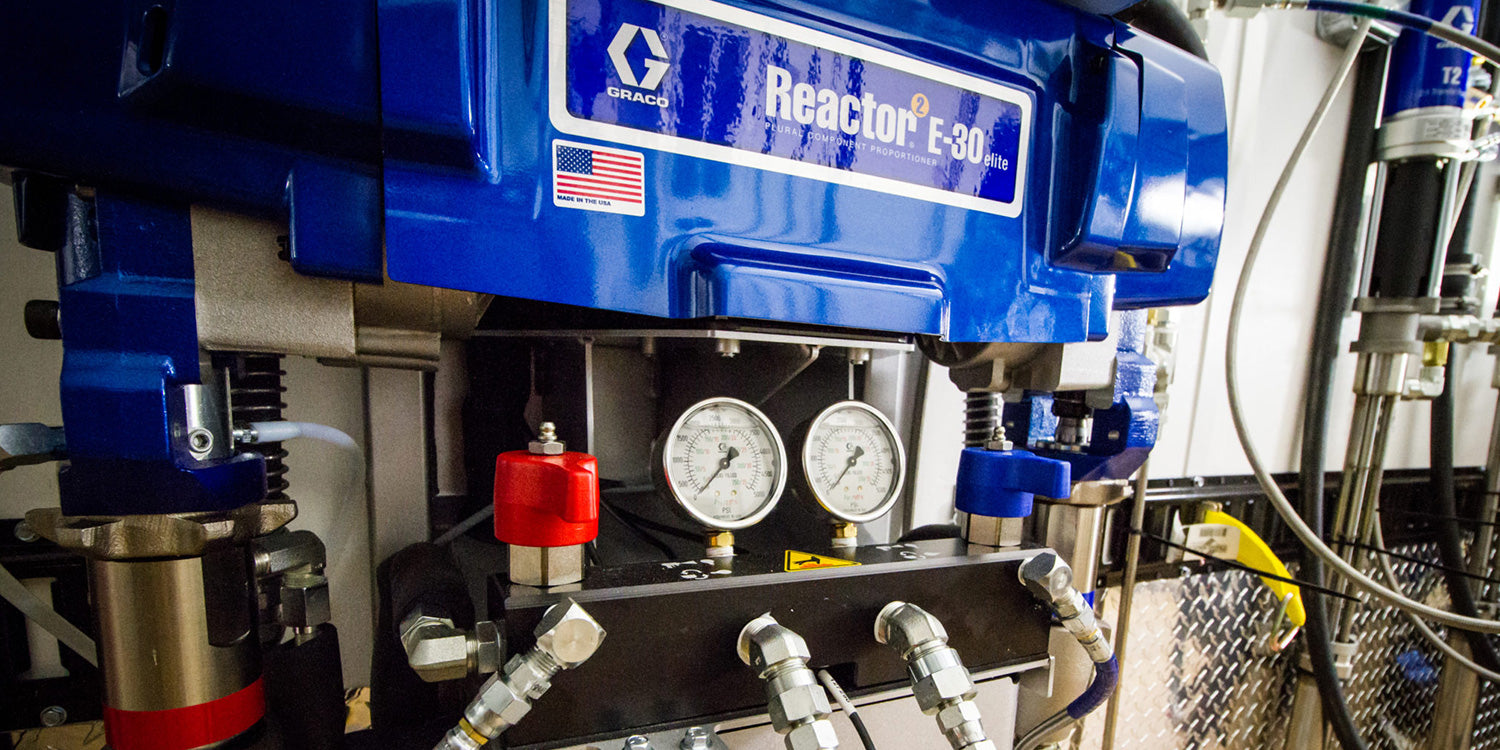

Before diving into maintenance, it's important to understand what proportioners do. They accurately mix various components of spray foam or coatings at the correct temperatures and pressures, crucial for the quality of the final product.

Regular Maintenance Tips

- Clean Filters Regularly: Filters should be checked and cleaned to prevent clogging and ensure smooth operation.

- Inspect Hoses and Seals: Regularly check for wear and tear to prevent leaks and maintain pressure integrity.

- Lubricate Moving Parts: Regular lubrication of moving parts can prevent wear and extend the life of the machine.

- Check Electrical Connections: Ensure all electrical connections are secure and in good condition.

- Monitor Temperature and Pressure Gauges: Regularly check these gauges to ensure they are functioning correctly, as they are crucial for proper mixing and application.

- Scheduled Professional Servicing: Besides daily and weekly checks, schedule professional servicing to address any complex issues and maintain optimal performance.

The Benefits of Proper Maintenance

Maintaining your proportioners not only extends their lifespan but also ensures consistent quality in your spray foam or coating applications. Regular maintenance helps prevent downtime and costly repairs, ensuring your projects stay on schedule and within budget.